EMPEROR

EMPEROR

The EMPEROR speaker was designed from its inception to

be the finest, reference class, full range electrostatic loudspeaker in

the world. It takes advantage of the improvements in electrostatic technology

over the past 20 years in every aspect of design.

..................................................................

The Emperor achieves this goal by combining the following criteria into

one, easy to use package.

1. FUTURE PROOF: The EMPEROR'S modular construction allows for future

upgrades in panel technology (film, insulation, screen spacing, and angle

of dispersion), High Voltage Power Supply technology and audio transformer

technology.

2. HIGH EFFICIENCY: THE EMPEROR is the first electrostatic "reference

speaker" which can easily be powered by Valve amplifiers with as little

as 35 watts of power or solid stte amplifiers with 50 watts of power.

4. INBUILT SUBWOOFER: Unlike other 'reference' speakers which require

satellite subwoofer sytems, the EMPEROR is able to reproduce low frequencies

(-3dB point approximately 15 Hertz when fully broken in) without any sonic

sacrifice. The sound is consistant in quality from 20 Hertz up to 45 kiloHertz

because we use the same 13 micron polyester film for subwoofer and full

range panels.

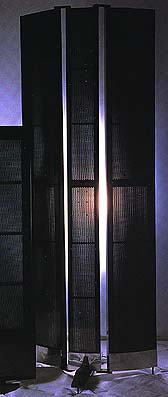

For deeper bass response, up to 20 bass panels can be added to virtually

create a solid 'wall of electrostatic' bass panels!

4. WIDE DYNAMIC RANGE: By dividing the full range panel at

around 150 Hertz from the subwoofer panels, the EMPEROR is able to generate

over 120dB of acoustic pressure from 30Hz - 45kHz (at ultra-low frequencies

of 15-20Hz, the spacing/film excursion limits the dynamic range to approximately

100dB reproduction at 20Hz).

COMPOSITION

SCREENS:

SCREENS:

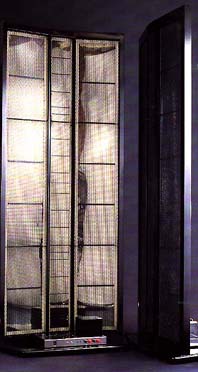

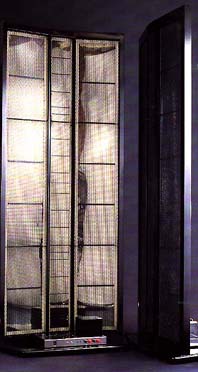

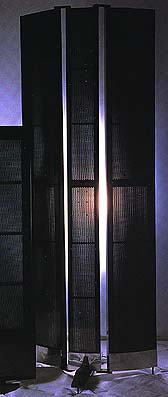

Each Emperor speaker is made up of a single 20cm (8") full range

electrostatic screen which has two 32cm (12") wide subwoofer screens

bolted via brackets on either side.

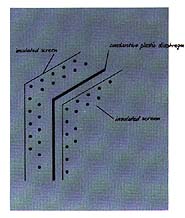

The screen stators are manufactured from copper-plated (6N) epoxy composite

board which is precision drilled and etched to remove the copper from the

edge boundaries of the holes. There are over 7000 holes drilled perfectly,

to within 1 micron which require two hours to drill. The panels are then

etched and coated and ultimately finished. A pair of EMPEROR consists of

24 panels which require on average 6 hours per panel to bring it to its

finished state.

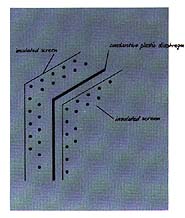

It is only by producing the stators in this way that we avoid the typical

insulation problem inherent in electrostatics using perforated steel. The

uneven insulation coating at the hole edges (refer to illustration) which

requires more insulation build up, reduces the available gap spacing.

The stators are supported by a welded steel frame which is epoxy-coated

and can be sand-filled for additional mass. The combination of epoxy stator,

special acrylic tapes and steel frames cancel any ringing - that would otherwise

be present. If you simply tap the frames you will hear a dull thud rather

than a 'ring'.

The copper is sealed using high voltage resistant two- pot epoxy coatings

which is further coated with a proprietory formula. Then the whole panel

is two- pot epoxy coated for a lustrous 'piano black' finish.

Copper is preferred to steel as a conductive stator material because of

its sound purity and excellent conductivity.

POLYESTER FILM

POLYESTER FILM

Our Polyester film was selected after 5 years of experimentation with various

types and grades of film. The earliest electrostatic designs used mylar

with a rubbed on graphite powder to retain the high voltage charge (QUAD).

Then came experimentation with conductive printer's ink (original MARTIN

LOGAN CLS).

Lately, almost all electrostatics have been using polyester which is covered

with a fine metallic film (normally used as solar insulation for windows).

All these methods are still prone to absorbing moisture because the particles

are simply glued with water base adhesives to the surface.

The EMPEROR uses a proprietory film which uses a fine stainless steel spray

of particles using a solvent based adhesive which is not affected by humidity.

If it is forced to arc, a small area of the film coating is sacrificed

to avoid any further damage . Even with 90% of the panel sacrificed, it

would still function with a minor loss of efficiency.

A special high conductivity adhesive is used to connect the copper strip

to the polyester film coating to allow the best long term electrical contact

which cannot be dislodged over time.

SPACING AND TENSIONING

The EMPEROR allows us to divide the conflicting requirements of small gap

(1.6mm) between screens and film for optimal treble performance and larger

gap (3.0mm) necessary to accomodate the maximum excursions at subwoofer

frequencies of the bass panels.

Tensioning is accomplished by hand using the same technique employed to

tension the diaphragm of a musical instrument (tympani, drum etc). After

one week of constant operation, the complete panel is heat treated to ensure

the tightness of the diaphragm before shipping.

It is recommended that the speaker is used constantly for at lease 6 months

to obtain its optimum modulus of elasticity. This translates to a significant

increase in efficiency, low level detailing and transparency.

SPEAKER FRAMES:

The individual steel frames used in the EMPEROR speaker are precision shaped

from welded steel to be ABSOLUTELY RIDGID under all circumstances. A small

radius is milled into the solid steel plates which create a fine arc- enough

to give a degree of extra ridgidity in the epoxy stators.

HIGH VOLTAGE SUPPLIES

By using the latest in polystyrene film capacitor technology in the treble

and polypropylene capacitors in the bass combined with ultra-high speed

rectifier diodes (35nanosecond), we are able to ensure that the High Voltage

supplies do not limit the low-level dynamic range and sonic resolution of

the EMPEROR.

NOTE: WARNING. THIS SUPPLY USES HIGH VOLTAGE WHICH CAN GIVE YOU A SHOCK.

NEVEr work ON THE SUPPLY WHEN IT IS CONNECTED TO THE MAINS AND MAKE SURE

WHENYOU DISCHARGE THE HV SUPPLY (BY SHORTING THE HV TO EARTH WHEN THE SUPPLY

IS NOT CONNECTED TO THE MAINS) BEFORE DOING ANY WORK ON THe SUPPLY.

AUDIO TRANSFORMERS

The art of winding Audio Transformers for electrostatic speakers or valve

amplifiers is missing from today's mainstream transformer manufacturers.

The transformer used in the EMPEROR are very special proprietory devices,

totally handwound and designed by a leading Australian audio transformer

fanatic after experimentation with over one hundred prototypes.

There are essentially three major factors which are inter related when designing

audio transformers. Unfortunately, all are conflicting and therefore require

compromise. For example, to increase the bass response one must add more

windings, which increases the capacitance and inductance and hence decreases

the treble response.

After coming up with the best compromise for impedance, capacitance, inductance

and gain, we set about experimenting with various transformer metals to

increase the power transfer before saturation. By using very expensive low

loss metal in our transformer stack, we are able to minimise the typical

dynamic compression of electrostatics. Because of this, the EMPEROR'S speed

and attack is reminiscent of horn type studio loudspeakers.

TREBLE TRANSFORMER: Our treble transformers use some very special

techniques. Firstly, we use 5 strands of Litzen wire for our Primary and

3 strands of Litzen wire for our Secondary windings. The inductance is minimised

by our 'heroic' use of 18 sections of windings to cancel out any stray inductance.Stray

capacitance and voltage breakdown is avoided by using 'double-insulated'

polyurethane coatings on OFC copper. This enables us to produce a transformer

which is PHASE PERFECT to well over 20KHz into a capacitive load of 1000pF.

Without the load, the frequency response is flat to beyond 200KHz.

BASS TRANSFORMER: By using every means to increase the absolute inductance,

we are able to produce a flat phase response to as low as 3Hz! The high

frequency roll-off starts at 5KHz, which is well beyond the 150Hz active

filter roll-off. This also allows us to add up to 20 extra bass panels per

side using the same transformer and power supply.

OPERATION

Biamplifier Operation: This is the recommended way to use the EMPEROR

which can be achieved in a number of ways:

*Using the phase linear active crossover supplied wire this in series with

the bass amplifier and use the volume pot supplied to match the overall

gain of the system for the bass section.

*For the Treble Section: Simple creating a 6dB/octave network by inserting

a capacitor in series with a full range amplifier input according to:

Ft (-3dB turnover frequency) = 1/ 2 pi (3.14) x R (amplifier

input impedance) x C (Capacitor in series).

Example: For an amplifier with an input impedance of 10 KOhms, and

we want the low frequencies to roll off from around 200Hz, the equation

becomes:-

200 = 1/2 x 3.14 x 100.000 x C

therefore C = 1/200 x 2 x 3.14 x 100.000

C = 7.96 x 10 power - 9 Farad

C = 7.96 nanFarad or 7.960 picoFarad

The closest value is approximaely 8.200 pico Farad which is available in

high quality polystyrene to minimise sound quality deterioration.

*Using an active crossover for both bass and treble (this is not the best

sonic solution because all active crossovers auditioned affect the sound

quality significantly).

DESCRIPTION

The EMPEROR is supplied with:

(a) two foam lined boxes which contain an individual speaker

(three panels).

(b) two cartons which contain the High Voltage Supply/Audio

transformers, colour coded connecting cables, assembly bolts

and active crossover for use in bi amplified systems.

9. INSTALLATION

The first step is to use the brackets and bolts upplied for each speaker

assembly to bolt the three panels together. These can be bolted as bass-treble-bass

or bass-bass-treble depending upon your room size (in narrow rooms, the

bass treble bass assembly is preferred).

After assembling the three panels, the long steel "foot" is bolted

to the underside of the treble panel to give the overall stability to the

speaker.

After assembly, the High Voltage Audio Transformer chassis should be positioned

behind each speaker with the colour coded safety banana sockets facing the

back of the speaker and the actual speaker terminals (two pairs of RED/BLACK

50AMp speaker terminals) should face away from the back of the speaker.

Once this is connected, use an appropriate IEC mains cable to connect the

HV supply to the mains which shoud light the neon positioned on the rear

of the HV supply case (make sure that the voltage of operation is set correctly

for your particular country).

SYSTEM POSITIONING

The correct positioning of the EMPEROR is critical to obtain a realistic

soundstage. Please ensure that it is at lease 2 metres (6ft) from the rear

wall and approximately 2 - 2.5 metres (6-8ft) apart. The speaker should

be angled inwards slightly to align the mid/treble panel with the listening

position.

......................................................

TECHNICAL FAULT SERVICING

If you have any problems, we suggest you FAX or e-mail us immediately to

discuss exactly what could be causing these problems. Because of the sheer

simplicity of construction, and modular approach used in the EMPEROR, faults

are easy to rectify.

(a) Arcing: If the speakers are arcing, it could be that there is some foreigh

matter dislodged between the film and speaker screen. Once this is 'burnt'

is should cuase no further problem.

(b) Losing Efficiency: Check the voltage supply voltages to ensure that

it is connected to the AC mains, or that a diode is not damaged.

(c) Panel Flapping: (TO BE CARRIED OUT BY MAS SERVICING AGENT ONLY) Using

a hairdryer, gently apply some heat (approx 1 - 2 feet away) in brushing

strokes until the slack is taken up.

Bass Level: The EMPEROR Treble panels are almost 8dB more efficient

than the Bass Panels and therefore you must increase the gain of the bass

channel by 8 dB . The Bass Level at approximately the 11 o'clock position

corresponds to 8dB gain increase.

Bass Rolloff Frequency: The crossover slopes of 6dB/octave are very

mild and hence it is very important to set the bass panel rolloff to a low

frequency- say 70Hz otherwise it will add too much weight to the sound of

the 'voice'.

All other Subwoofers use very steep rolloffs of 18dB/octave to avoid the

smearing of midrange frequencies. This also has the undesirable effect of

destroying important transient and phase relationships in the low frequency

region at crossover - avoided in the EMPEROR with 6 dB slopes.

The only problem with 6dB slopes is that crossover must be at very low frequencies

which is not a problem with the EMPEROR Treble panel which in fact can easily

reproduce down to 20Hz, but is restricted because of stator spacing to avoid

frequencies lower than 50Hz.

FINISHES: The EMPEROR can also be 'framed' in cherry wood or any other finish

you desire. Another option is to incorporate the EMPEROR into the design

of a special AUDIO room. Our or your appointed Architects/Interior designers

can assist with these options.

FULL-RANGE SPECIFICATIONS: Efficiency: 96- 105dB/W/metre,depending on amount

of panels used.

POWER HANDLING: 100-500WATTS music power.(depending on panels)

FREQUENCY RESPONSE: 20Hz-55kHz +/- 3dB.

DYNAMIC RANGE: 120dB.

STEP-UP TRANSFORMER: 100:1 ratio. 18 individual sections wound clockwise/anticlockwise

to reduce overall capacitance. Six (6) Ohm primary impedance. 300 Ohm secondary

impedance. Bifilar wound with double-polyurethane coated AUSTRALIAN COPPER

wire Litzen. Low-loss grain-oriented steel laminations on a 200 WATTS E-I

core. Totally handmade, wound and assembled.

SUBWOOFER BASS PANEL SPECIFICATIONS:

Efficiency: 90dB/W/metre, POWER HANDLING: 100 Watts program.

DYNAMIC RANGE: 2 panels/side :120dB 40Hz-100Hz, 105dB 20Hz-100Hz,

4 panels/side: 130dB 30Hz-100Hz

20 panels/side: 145dB 15Hz-100Hz efficiency 110dB/W/metre!

STEP-UP TRANSFORMER: Turns ratio: 100:1

FREQUENCY RESPONSE: 2Hz-5kHz into capacitive load.

[The Company | Unique Technology | Products

| Coming Soon]

Contact Us!

home!

EMPEROR

EMPEROR SCREENS:

SCREENS: POLYESTER FILM

POLYESTER FILM