|

back to www.audiodesignguide.com |

To get more information contact me at: webmaster@audiodesignguide.com |

INTRODUCTION

After many years

designing single ended amplifiers I have decided to start a series of

test

about the Push Pull amplifiers.

These amplifiers are considered at a lower level than single ended but if you

want a power enough to drive ESL loudspeakers and low distortion systems like

Audiotechnology,

Dynaudio,

Scanspeak,

Morel and

Seas there is no other choice.

The main problem of Push-pull amplifier is the not perfect distortion decay with

the

cancellation of even harmonics but if

we keep the distortion level very low this consequence can be ignored and

the sound will not be affected.

Another

characteristic of many Push-pull amplifier is the high global feedback used to

get a good damping factor because to increase the output power often are used

output transformers with low turn ratio.

As my others amplifiers to preserve the signal I have used the minimum number of

components on the signal path so only one inter stage capacitor is present.

Here I would like to create a Push-pull taking only the benefits of this design

and

minimizing the bad effects.

This amplifier, like the my other designs,

can be connected directly to

a CD Player or to a DAC without using a pre-amp.

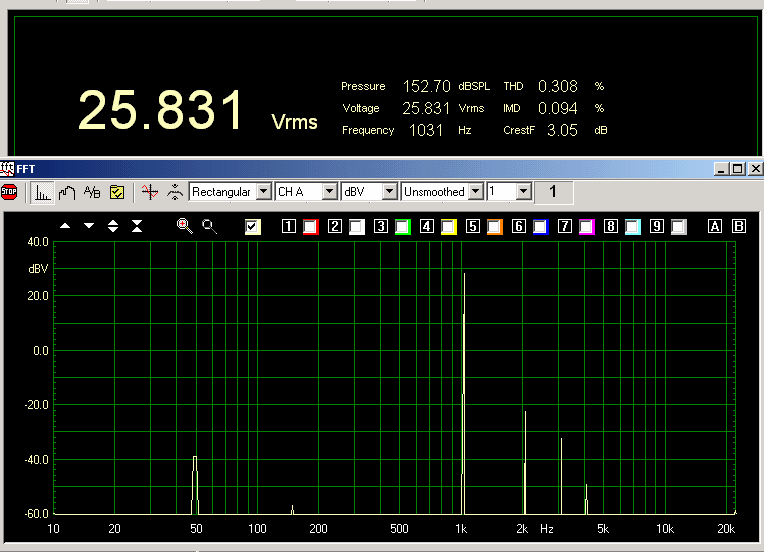

update 23 Feb 2016

Some modification by B-LAB of Stefano Bianchini

Vout=20Vrms with less than 0.5% thd so about 50w on 8ohm

Vin=0.962 Vrms to get 50w

Output impedance near to 0.5ohm

Frequency band 13-20KHz at -0.2db

Global feedback about 4.5dB

This amplifier give an incredible good sound on any

loudspeakers, tested on the my Monitor 2 e Hi-efficiency system.

TUBES

|

To create a push

pull amplifier

is possible to use triode and pentode but obviously to test many configurations

like the ultra linear we need a pentode. There are many pentode good for audio amplifiers but the most common in the current production are the EL34, 6550 and the KT88 so follows a compare table with the main characteristics and price:

The

output plate

characteristics have been measured with the Sofia computer-controlled

curve-tracer by Audiomatica

and I have added the lines to calculate the internal/plate resistance. |

|

|

To get the best

result use matched quad tubes available in the shop

thetubestore.com or

pmcomponents.co.uk. As driver tubes I have used the Jan Philips series to get the best sonic result. In this amplifier it is possible use any kind of 12AX7, ECC83, E83CC, CV4004 and 12AU7, ECC82, E82CC, 5814 without change other parts. The power supply fix the filaments reference at +80v instead of 0v so to consider the max cathode to heater voltage. |

In the datasheet is mention this limit:

| tube model used | max cathode to heater voltage (max Vkf) | circuit cathode voltage (Vk) | heater voltage (Vf) | Vk - Vf |

| ECC83 / 12AX7 | 180v | 20v | 80V | 60V |

| ECC82 / 5814 / 12AU7 | 180v | 246V | 80V | 166V |

| EL34 | 100v | 1V | 80V | 79V |

The circuit cathode voltage (Vk) is calculated with:

EL34 current = 46mA

Resistance on cathode = 47 // 47 = 23.5ohm

Cathode voltage = 23.5ohm * 46mA = 1V

ECC83 current 1mA

Cathode voltage = 20V

ECC82 current 6mA

Resistance on cathode = 82K // 82K = 41Kohm

Cathode voltage = 41Kohm * 6mA = 246V

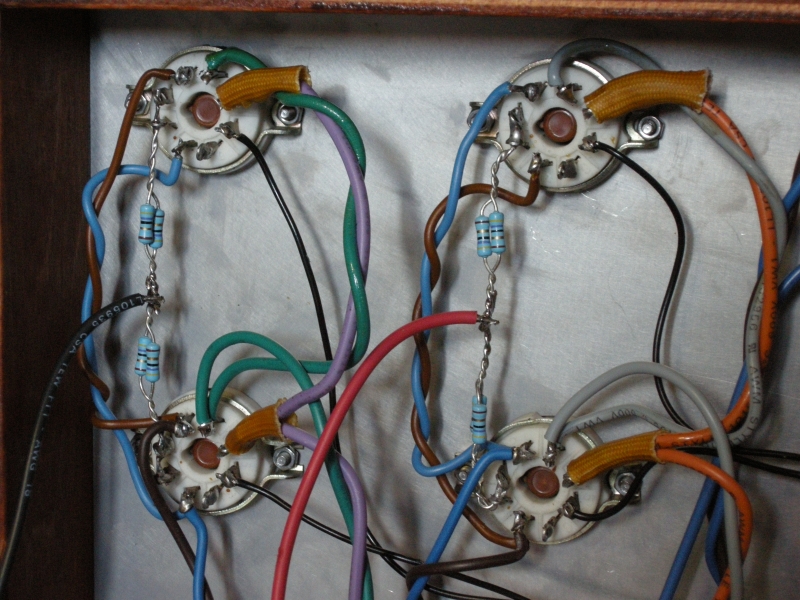

ECC83 and ECC82

sockets, bottom view. |

EL34 Socket, bottom view

|

2N5459 pin

|

BC546B pin

|

TRANSFORMES

2 x Bartolucci 557E

Nominal power 50w

Primary impedance 4500 ohm

Primary Inductance 36 H

Primary resistance 64ohm

Weight 4 Kg

Secondary grid at 40%

1 x Bartolucci

Nominal power 400w

Primaries: 2 x 115v

Secondaries:

2 x 350v 0.4A

2 x 6.3v 9A

1 x 100v 0.1A

The price for the complete set of these

transformers is about

400 + tax 20% (3 item).

PHASE INVERTER

|

In all the push-pull amplifiers is necessary a phase inverters to split the unbalanced input signal into two balanced signals out of phase by 180 degrees to drive the push-pull output tubes. The performances of this phase inverters is very important and it affect the final result of the amplifier. Most push-pull amplifiers use the the split load or the paraphase but both have a lot of disadvantages.

The split load without a regulation

give two precise outputs with the same level but the output

impedance are completely different so it should not be used to drive

directly difficult load like the final stage. These first two schematics are parts of Bartolomeo Aloia amplifiers. To get the best performances

with the minimum

components I have decided to use the differential stage seen in the most

of solid state amplifiers. |

|

|

|

SCHEMATIC

In the triode connection the power is limited and the

damping factor is not enough good also if we use the cathode feedback of the

transformer secondary.

So I have decided to switch to the ultra linear connection also if this mean go

near to the pentode configuration with an inevitable increment of the internal

resistance of vacuum tubes, see test here.

Using this connection we get also more voltage gain in the final stage so the

cathode feedback of the transformer secondary compensate the increment of

internal resistance of vacuum tubes and the output impedance without a global

feedback is only about 4ohm.

This output stage design with both cathode feedback and ultra linear is inspired

to the AudioResearch reference amplifiers.

To have enough voltage gain to use global feedback

I have inserted in the first stage to a hybrid cascode with vacuum tubes and fet.

The input fet used in this amplifier create a very good result maintaining a

simple design and this should not persuade

you to love this design.

It is possible see in many AudioResearch

vacuum tube reference amplifiers the fet in input stages.

This driver stage give these performance:

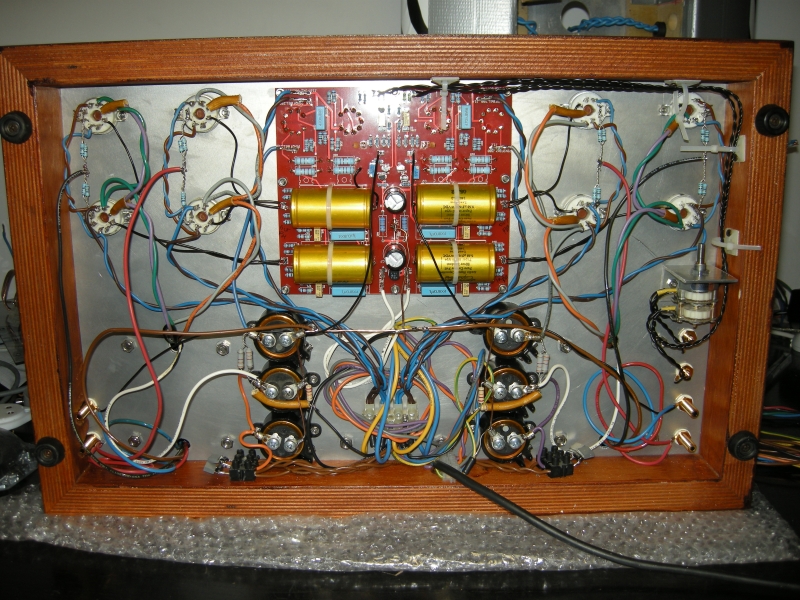

PCB

The driver stage of this amplifier is a little bit complex so I have decided to create a pcb

using Eagle Cad.

Follows the schematic of all the parts included in the pcb.

R1,R2,R4,R5,R30,R37,R38,R47= MF50 470K 0.5W 1% cod. Farnell 934-0645

R21,R22,R23,R24,R61,R62,R63,R64 = MF50 220K 0.5W 1% cod. Farnell 934-0220

R11,R12,R51,R52 = 1Mohm 1% 0.25W

R7,R32 = 100ohm 1% 0.25W

R9,R50 = 22K 1% 0.25W

R6,R8,R48,R49 = 1Kohm 1% 0.25W

R13,R14,R53,R54 = 2Kohm 1% 0.25W

R15,R16,R55,R56 = 47Kohm 1% 0.25W

R25,R26,R65,R66 = 27Kohm 1% 0.25W <<< reduced

to have about 20-22V max on jfet drain

R17,R18,R19,R20,R57,R58,R59,R60 = 82K 2W

R39 - R46,R73 - R80 = 2Kohm 1% 0.25W

R3,R31 = 500ohm multiturn trimmer Spectrol 64

R10,R36 = 1Kohm multiturn trimmer Spectrol 64

R29,R33,R69,R70 = 10Kohm multitrun trimmer Spectrol 64

R81,R82 = 6800ohm 2W

C1,C3 = 22pF ceramic or silver mica

C9,C10 = 470nF 250V PHE426 MKP cod. Farnell 157-2144

C2,C4,C5,C6 = 0.68uF 630V Jensen copper film paper in oil

CX1,CX2,CX3,CX4 = 1uF 250V PHE426 MKP cod. Farnell 157-2145

C7,C8 = 100uF 200v any electr.

V1,V3 = 12AX7, ECC83, E83CC, CV4004

V2,V4 = 12AU7, ECC82, E83CC, 5814

Q5,Q6 =

2N5459

DRIVER MEASUREMENTS

FINAL MEASUREMENTS

PHOTOS

TEST SYSTEM

MATERIAL SOURCES